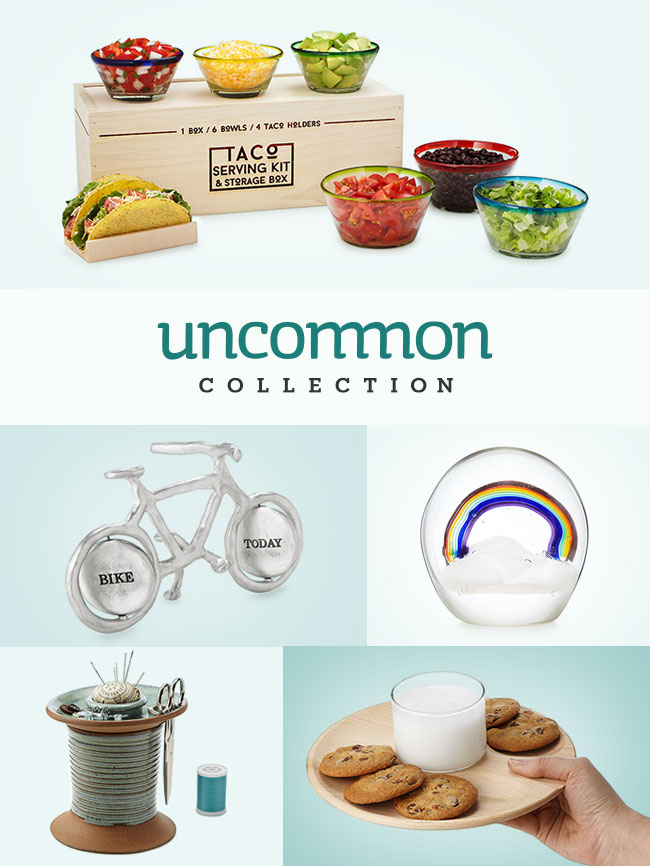

Roughly a year ago, we proudly launched The Uncommon Collection. While all of our goods are “uncommon,” the Collection is special because it’s a culmination of efforts to create an assortment of well-designed items made responsibly by businesses who embrace thoughtful and sustainable business practices. The Collection presents opportunities for our manufacturing partners to share the spotlight with their products, telling the stories behind those products and connecting our customer with the people who made them. We have grown a lot since introducing the Collection last year, both in terms of number of items and makers contributing to the Collection and in our understanding of the challenges and opportunities such an initiative presents.

What we’ve learned:

Companies come in all shapes and sizes

We approached the development of Collection criteria based on values we as a company hold ourselves and devised for manufacturers in a general sense. At UncommonGoods we work with companies both large and small, in widely varying industries employing teams all across the skill-level spectrum. It was important to us that this not be an initiative with criteria that artificially closed us off to certain industries or company sizes, but rather was as potentially broad-reaching as possible to raise the bar for as many companies as possible.

We sought to re-imagine Francine’s design by incorporating sleek and clean lines and components, and providing enough capacity for even the most ravenous snackers. In doing so we needed to identify the attributes important in making the original design functional and effective. As

We sought to re-imagine Francine’s design by incorporating sleek and clean lines and components, and providing enough capacity for even the most ravenous snackers. In doing so we needed to identify the attributes important in making the original design functional and effective. As

Conclusion

Conclusion