It’s hard to believe that we’ve been running our Studio Tours series for almost 5 years. Maybe that’s because every time I step into a another studio, I feel like I’m entering a whole new world. Over the years I’ve visited jewelry makers, potters, woodworkers, and even an industrial kitchen. And that’s just to name a few. Every time I leave an artist’s space, I feel creatively refreshed and ready to get making myself.

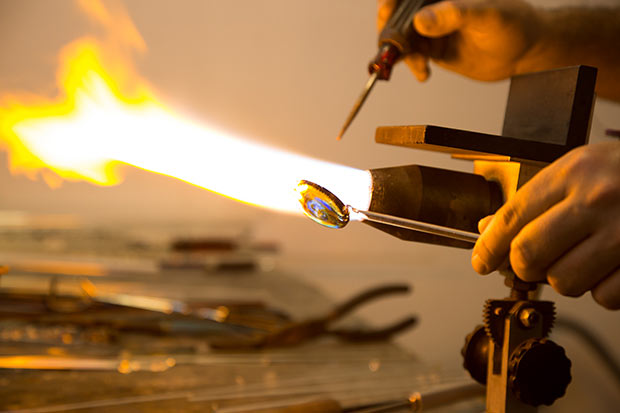

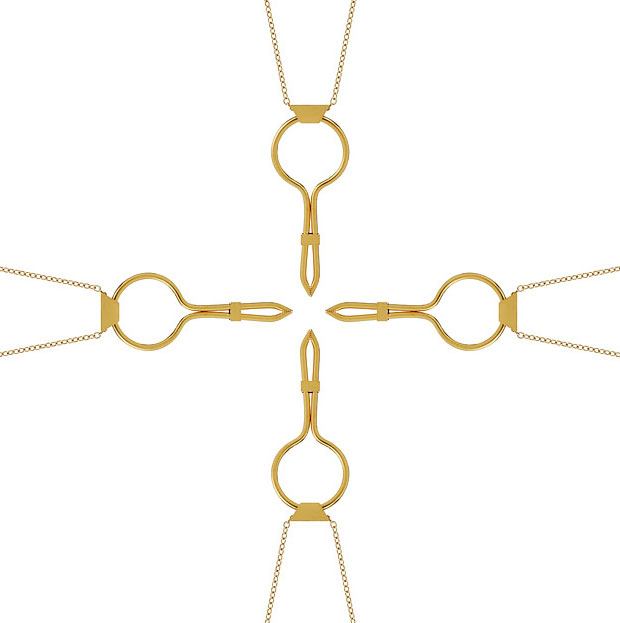

In 2016, I actually did get in some hands-on experience, when Jim Loewer gave our team a tour of his Philadelphia glass-working studio and let me use the torch to make own pendant. It was was definitely as much fun as you’d expect playing with fire and molten glass to be, and I now have a memento from the visit. Other adventures this year included checking out a sustainable studio made from reclaimed shipping containers, one contributor’s trip to London to meet world-renowned jewelry designer Alex Monroe, a look inside our own Product Development team’s creative space, and more. It wasn’t easy to pick just a few highlights from each Studio Tour to show you, but here are some moments that I hope spark your interest and maybe even put you in the mood to get creative too.

Laurel Begley

Laurel Begley’s Personalized Faux Bois Vase includes a symbol of lasting love, so it’s no surprise that she told us about some of the symbols of love an nurturing in her own life as she gave us a virtual tour of her Santa Rosa, CA, studio. She also shared some great advice: “Don’t try to be anything you’re not. Do your best work, put it out there, and everything else will fall into place.” | Visit Laurel’s Studio