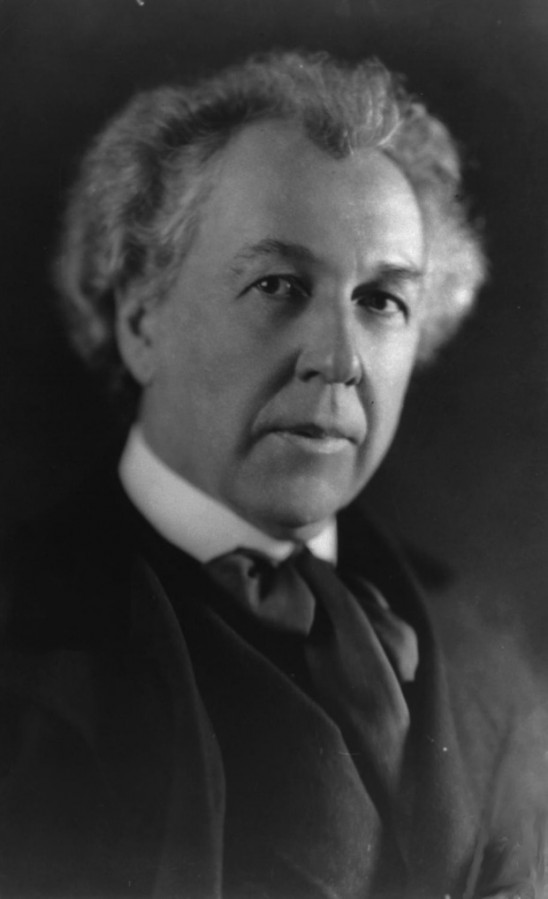

When I saw the sample of our new Prairie Bird Feeder from across the room, I recognized its inspiration instantly: the so-called “Tree of Life” art glass pattern—probably the best-known motif from Frank Lloyd Wright’s Buffalo masterpiece, the Darwin D. Martin House.

But I suppose I should be able to spot such patterns at 50 paces. After all, I spent nine years as curator for the Martin House Restoration Corporation, helping to preserve, document, and share such designs with the public. I stopped short of getting a Tree of Life tattoo, but you might say that the Prairie style is in my blood.

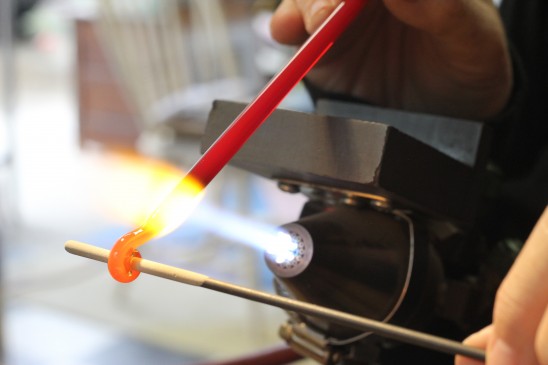

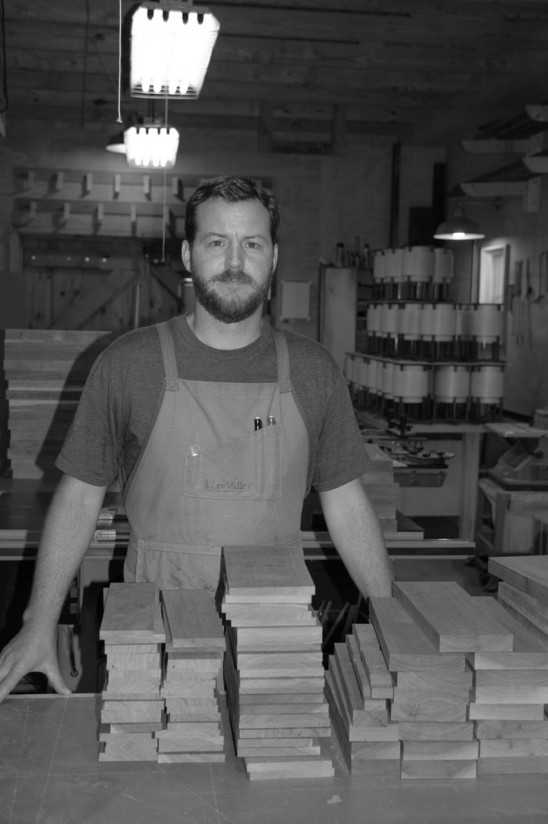

Frank Lloyd Wright designed in concert with Nature—with a capital N, he insisted—and Drew Kelley’s Wright-inspired bird feeder design follows that organic lead. The cedar feeder is simply stained as Wright might have done, and its miniature roof is gently pitched and cantilevered like the rooflines of the Martin House and other homes of Wright’s Prairie period (c. 1900-1914). Add the art glass motif applied to the side panels, and those birds will be eating in sublime style.

Wright’s birdhouses feature multiple chambers in a colony-like configuration favored by purple martins. So, scholars suspect that the birdhouses were, in part, a play on the name of the client (martin / Martin). And like purple martins, the human Martins lived communally, with extended Martin family (Darwin D. Martin’s sister Delta Barton and her family in the smaller house in the complex) and servants living in the same complex. Beyond Buffalo, Wright also designed a custom birdhouse for the Westcott house in Springfield, Ohio.

Despite this dazzling portfolio, you can safely say that at least a few of Frank Lloyd Wright’s designs were for the birds…and so is our new bird feeder.